Period of services: 2016 – 2018

Project value: $40 Million

Location: Kibali Gold Mine, Haut-Uele Province Democratic Republic of Congo

Key aspects: 10.1 MW Run-of-River Hydro Electrical Project

Client: Randgold Resources - Kibali Gold Mine

Project description:

The Azambi Hydro Electrical Project on the Kibali River, Democratic Republic of the Congo at the Kibali Gold Mine, which is a joint venture between Randgold Resources, AngloGold Ashanti and the government of the DRC to supply reliable, cost effective electricity to Kibali Gold Mine. It is the third hydroelectric plant constructed for Kibali Gold Mine, the others comprising Nzorro 2 and Ambarau HEP, the latter which is located upstream from Azambi.

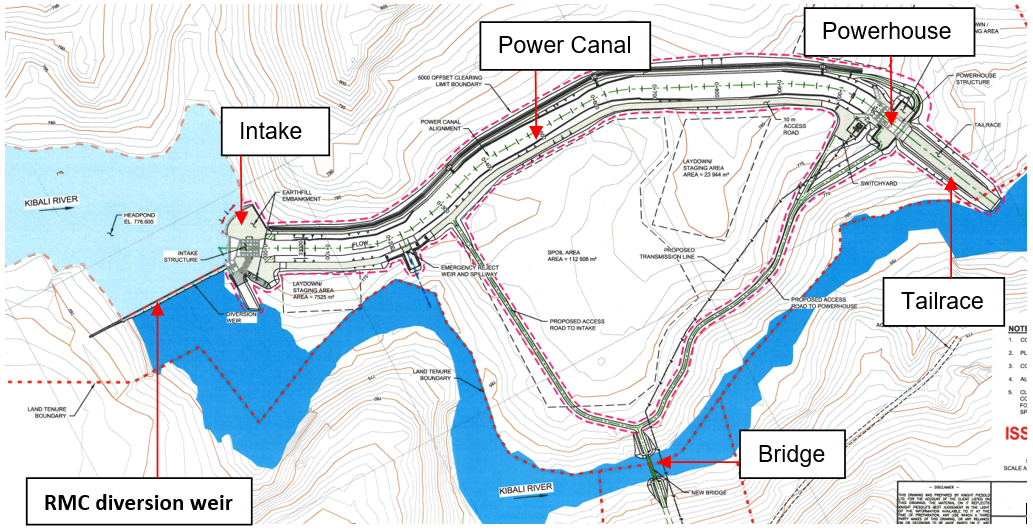

The Azambi HEP is a run-of-river type 10.1 MW facility operating over a gross head of 14.7m. Its main features include a diversion weir, concrete intake structure, 1.06 km long power canal, concrete powerhouse with twin Kaplan turbines, electric generators, switchyard and 7 km long 66 kV transmission line. Drilling and blasting was required over most of the project footprint, in order to attain the desired foundation levels and waterway profiles.

Overall plan of the Azambi HEP with its 45m wide, 1.06 km intake power canal, feeding into the hydroelectric powerhouse, and 200m tailrace.

Image of inlet works with diversion weir on right with power canal flowing to powerhouse in the left.

Scope of services:

Design, supervision and monitoring of all drill and blast works required for the bulk excavation works at the project which included:

• Intake

• Power canal:

• Powerhouse

• Tailrace.

Located in a very remote area with a very limited selection of plant, available drilling equipment available included Atlas Copco top hammer T35 and T45 rigs equipped with T45 and T51 extension rods and 51mm to 89mm drill bits. Explosives supplied by Kibali Gold Mine ranged from water-gel cartridge explosives to pumped bulk explosives.

Very tight excavation tolerances were enforced especially at the Powerhouse, Tailrace and Intake which required pre-split and cushion blasting on tight patterns.

Top: Presplit completed for Tailrace; Second: Powerhouse before blasting; Third: Powerhouse after blasting and bottom: Power Canal after excavation